Description

The glued frame, processed inside and outside, various trims and accessories are assembled into a sofa. The general process is to nail the inner sleeve on the frame glued with sponge, then put on the outer sleeve and fix it, then put on the decorative parts, nail the bottom cloth and install the feet.

The glued frame, processed inside and outside, various trims and accessories are assembled into a sofa. The general process is to nail the inner sleeve on the frame glued with sponge, then put on the outer sleeve and fix it, then put on the decorative parts, nail the bottom cloth and install the feet.

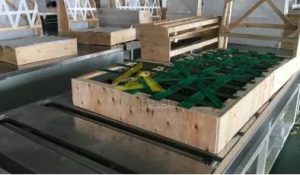

After assembling into a complete sofa product, it can be packed and put into storage after passing inspection.

Zhejiang Aimas Intelligent Equipment Co., Ltd

From 1992 to the present, we have always believed in creating greatness.

We are a professional mattress intelligent production line manufacturer, from “Iron Horse Automation” to “Emmaus Corporation”, “Emmaus Eight Tower Robot” has experienced more than 30 years of hard work.

Along the way, we focus on the mattress production equipment field, from a heritage of precision manufacturing of the old enterprise developed into today’s subversion of the mattress traditional manufacturing technology of intelligent robot application system, with industry awareness and reputation of the excellent enterprise.

The next 5-10 years will be the mattress manufacturing industry reshuffle period, intelligent manufacturing will certainly replace traditional manufacturing, if you have recent ideas to change the production model, please contact us to learn more about the mattress production line equipment, so that Industry 4.0 really help your business to create wealth!